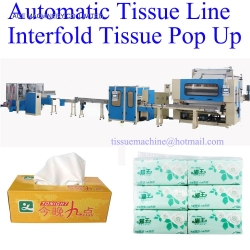

fully automatic facial tissue production line with auto transfer to packing machine

China fully automatic facial tissue making machine with packing

This China fully automatic facial tissue production line consists of facial tissue making machine, facial tissue log saw cutting machine, automatic soft facial tissue packing machine and automatic facial tissue box packing machine. It is mainly used for the production of boxed facial tissues, soft drawing facial tissues and v fold paper towels. The production line has changed the low-output production mode which requires many machines and much labor.

The whole production process goes like this: raw paper fed into the folding machine and folded facial tissues

output, slit and sorted automatically and loaded into box packing machine or plastic packing machine. Thus,

the quality of finished products and yield of products are improved, labor cost reduced, and the high quality

and good performance of machines earns trust from new and regular customers. This production line is

exported to Europe and Southeast Asia and other markets, has won the praise of the new and regular

customers. It adopts advanced PLC computer programming system and speed adjust by inverter, automatic

stacking unit. HMI operation panel to input all data.

Technical specifications of this fully automatic facial tissue making machine with packing are as below for your reference.

|

Fully Automatic Facial Tissue Production Line |

|

| ACE-V200-6L Fully Automatic Facial Tissue Making Machine with Auto Transfer | |

| Jumbo roll size |

a. Jumbo roll specification:13-50 g/m² 2-ply facial tissue paper, airlaid or nonwoven or Other requirements to be specified. b. Jumbo roll size: width ≤ (400 - 3500)mm x Φ1500mm;(Other size available.) c. Jumbo roll core diameter:Φ76mm; |

| Machine Speed | Operating Speed: about 130 meter/minute, fastest facial tissue machine in China now. |

|

Product size |

Facial tissue open size: (200 x 200mm) ±2mm. Other size, please specify. Facial tissue folded size: (100 x 200mm) ±2mm. Fixed size(cylinder cutoff size) is 200mm. The cutting length is adjustable by the log saw. |

|

Folding type: |

V fold interfold and Vacuum folding type. |

| Unwinders |

a. With 2 jumbo roll unwinders stands, each jumbo roll is controlled by an independent motor, NOT traditional chain driving. b. Jumbo roll web tension is adjustable. c. Pneumatic loading Jumbo roll automatically; |

| Folding Unit |

a. Automatic left-right stagger counting unit or ink mark. b. Independent Floor standing wallboard structure (thickened full steel plate support structure)。 c. With stepless-adjustment hand wheels to control web tension. |

|

Full Embossing unit |

a. With 2 pairs of steel-to-rubber full embossing unit. (Embossing pattern provided by the buyer or recommended by us.) b. Embossing tension is adjustable to adapt the machine for different quality and gsm papers. c. Strong structure. Steel to paper or Steel to steel embossing unit optional. |

| Edge Embossing Unit | Optional. |

| Control System |

a. Design speed: 130meters/minute b. Operation speed: 130meters/minute, about 1200 sheet/min/lane * 6 lanes, depends on tissue gsm, quality, operator etc. c. Speed of production is controllable. d. Main motor control by inverter e. Controlled by inverter, famous brand. f. Automatic left-right stagger counting system or ink mark, each stack of 100 pieces, 150pieces, 200 etc. g. With JOG function for folding unit, embossing unit etc. easier for maintenance. h. With emergency stop function for folding unit, embossing unit etc. you can stop the machine in any cases of emergency. Good for safety protection. i. With paper break auto stop function. Machine will automatically stop if paper break or used up. With Taiwan Longtech Vacuum Pump. |

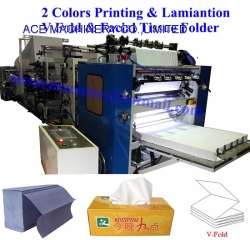

| Lamination Unit |

point to point lamination unit nested to nested lamination unit. |

| Machine Power |

Main Motor about 7.5KW, With Taiwan vacuum about 15 KW, (final Power is subject to actual power KW without further notice.) 3-phase AC380V 50HZ or 3phase 220V 60hz or customized. |

|

Machine weight |

about 4500kg. |

|

Machine size |

6000x1800x2100mm. |

|

|

|

| ACE-FLS Automatic Facial Tissue Paper Log Saw Cutting Machine | |

| Model No. | log saw |

| Machine structure |

single lane / single channel / single line. Optional double lanes machine. |

| Working material |

facial tissue paper interfold napkin pop up tissue napkin interleaved tissue paper interfold hand towel V fold hand towel Z fold hand towel M fold hand towel |

| Log saw cutting speed |

Designed speed: 300 cut/minute Working speed: 0 - 300 cut/minute, depends on tissue size. |

|

Cutting sizes ranges |

L 60-300mm adjustable W 60-110mm or customized H 25-200mm or customized. |

|

|

|

|

ACE-FSP Fully Automatic Single Bag Soft Facial Tissue Paper Packing Machine |

|

| Packing format |

Single bag facial tissue soft packing machine. |

|

Packing speed |

high speed about 0 - 200 packs/minute. |

| Packing tissue size |

L100-230mm Other sizes to be specified. W100-140mm H40-150mm |

| Control system |

PLC programmed control, Siemens or Mitsubishi Inverter for variable frequency speed control, Touch screen for operation Servo motor control. Equipped with automatic coding system to automatically print the manufacture dates on each package of the tissues. Equipped with perforating system to make perforated dotted lines on each package of tissues so that the customers can easily open the bag and take the tissues. |

|

|

|

|

ACE-FBP-40 Fully-Automatic Facial Tissue Box Packing Machine |

|

| Packing tissue box size |

L: 100-240mm other sizes, please specify. W: 100-120mm H: 30-100mm |

|

Packing speed |

about 40- 50 pack/min. optional high speed 120 box/minute. |

|

|

|

Video of this fully automatic facial tissue making machine with packing for your reference.