4 Lanes High Automatic Speed Junior Low Fold Dispenser Napkin Making Machine

Automatic 4 Lanes High Speed Junior Low Fold Dispenser Napkin Making Machine in China

Automatic low fold dispenser napkin manufacturer in China

Application

This ACE-LNM-4L 4 Lanes High Automatic Speed Junior Low Fold Dispenser Napkin Making Machine is mainly used to automatically fold, emboss, print, cut and count 1/4 L fold dispenser napkins, l shape dispenser napkin, L folding dispenser napkin, 1/6 book fold dinner napkins, low fold dispenser napkin, nonwoven airlaid napkins and MG paper napkins etc. It adopts vacuum folding style. The mainly function of this machine is to manufacture easy-to-take one by one plain, embossed and LOGO printed and laminated dinner tissue paper napkins. It has 4 lanes output and can run at very high speed up to 2800 sheets per minute. It is an ideal equipment to manufacture away-from-home tissue paper products.

Please check out this link for more high speed tissue paper napkin machines.

Below video for your reference. Or please check out this video link of this high speed junior low fold napkin dispenser machine for your reference. Video link: https://youtu.be/C3pGX4iCHCk

Advantage:

1 Machine for L fold low fold dispenser napkins

2 high speed up to 2000 sheet/min

3 Embossed and printed and laminated

4 Vacuum fold style

5 Vacuum fold 1/6 low fold dispenser fold

Quick details:

1 Size 170x170mm

2 Steel to paper embossing unit

3 Four lanes output

4 Vacuum fold 1/4 or 1/6 dispenser fold

Technical parameters as below

|

Model |

ACE-LNM-4L |

|

Output type |

4 lanes low fold dispenser napkin machine |

|

Folding speed |

2000 piece/min, depending on the paper quality and napkin size. |

|

Raw paper |

13-20g/m2 2-ply, 16-45g/m2 1-ply, wooden pulp paper or nonwoven airlaid. Other sizes please specify. |

|

Jumbo roll size |

≤ 1320mm x Φ1200mm (Depends on your napkin size, customized) |

|

Napkin unfolded size |

330mm x 330mm or Customized. |

|

Napkin folded size |

165mm x 140mm adjustable. One size is fixed. One napkin size is adjustable, by paper roll width. |

|

Folding type |

Vacuum folding Dispenser L fold low fold 1/4 1/6 fold etc.. |

|

Embossing unit |

1- Steel to paper(wool), Male to female. (Steel to steel is available.) 2- Embossing pattern can be any LOGO, brand name, flowers etc. 3- Embossing pattern can be customized by client or recommended by us 4- Controlled by screws, mechanical pressing type. Cylinder type is optional. |

|

Printing unit |

1- Flexo printing type. 2- Printing colors customized up to 8 colors. 3- Printing Logo is changeable. You just need to change the Printing Rubber only. 4- Anilox printing roll. Ceramic anilox roller. 5- Printing roll is adjustable. 6- Ink printing system to be negotiated. 7- With doctor blades. 8- Closed chamber ink circulating system. |

|

Tension control |

Speedless Tension control unit to fit the machine for paper of different quaity and different gsm. With automatic web guiding system. With automatic web tension control system. |

|

Calendar unit |

Make the napkin softer. |

|

Counting |

Automatic counting unit |

|

Emergent stop |

Emergent stop unit to inspect any paper breaks, paper jams. |

|

Paper feeding |

Synchronizer for feeding paper |

|

Power |

7.5Kw for main motor, 11kw for vacuum pump (3-phase AC380V 50Hz or customized) |

|

Machine size |

7x2x2m |

|

Weight |

4000KG |

|

Videos and photos available. |

|

ACE-LNM-4L High Speed Four lanes vacuum low fold dispenser napkin Machine

Technical parameter:

A. back stand

1. Parent roll specification: single or double plies tissue paper.

2. Parent roll size: ≤Φ1100 x 1320mm (330mm * 4lanes = 1320mm) Diameter x Width

3. Core inner diameter: 76mm

B. Feeding Section

1. With One jumbo roll stand.

2. Pneumatic cylinder control

3. Stepless adjusting speed to control web-tension of paper.

4. Auto adjustment setting

5. With pneumatic system to automatically load jumbo rolls.

C. Embossing Section

1. One set of steel to paper embossing unit. (Embossing pattern provided by client or recommend by us)

2. Mechanical press type or pneumatic control.

D. Printing Section (advanced design.)

1. With 2 colors flexo-graphic printer section.

2. Printing unit with driven by timing belts to make printing more precise.

3. Simple and easy adjustment of horizontal and longitudinal registration by turning hand wheel.

4. With automatic printing roller disconnection device during machine stop. If the machine stops, the roller will automatically disconnect with the printing unit, controlled by pneumatic system.

5. The printing plate roller can be adjustable or disassembled from the printing unit, much easier for the operator to attach the printing rubber plates or clean the roller.

6. Both sides of Anilox roll & Rubber roll with buffer for anti-spill cover to stop the ink spilling out of the ink tank and spraying somewhere.

7. The printer is equipped with cover on the in tank to prevent the inks spilling out of the ink tanks.

8. With printing ink reservoir for reserve dropping ink and avoid ink dropping on machine or place to keep environment clean.

9. Equipped with closed chamber ink circulating system.

10. Adopts ceramic anilox rollers for printing.

E. Folding Section

1. Unfolded size: 330x330mm

2. Folded size: 165x140mm adjustable

3. Fold type: 1/4 1/6 low fold dispenser L fold.

4. Synchronizer for feeding paper

5. The gap between 2 folding cylinders can be adjustable to fit for papers of different gsm and different quality.

6. With 4lanes output delivery.

7. Capacity: about 700 piece/min/lane x 4lanes = 2800 piece/min total, depending on paper quality, gsm and workers operation.

8. With automatic counting unit. With single tissue pop up every count.

9. Automatic counting function: counting range: 0-9999 sheet per count, adjustable.

C. Control system

1. Controlled by Taiwan DELTA inverter, NOT like others using inferior buttons which is bad.

2. With variable frequency speed control motor, NOT like others use electric magnetic speed regulation motor which is bad.

3. With alarm system when the machine starts or paper breaks or emergency stops.

4. With JOG function.

5. With emergency stop function.

6. With auto sensors for detecting paper breaks or used up. Machine will automatically stop if paper breaks or used up.

7. Famous brand motor.

8. Power: 7.5Kw for main motor, 11kw for vacuum pump (3-phase 380V 50Hz or customized)

9. Pressure: 0.5MPa.

10. Machine size: 7x2x2(M)

11. Weight: about 4500 kg

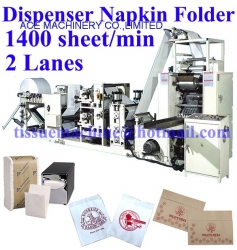

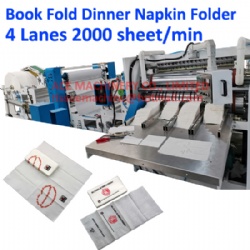

Picture of this low fold napkin machine for your reference.