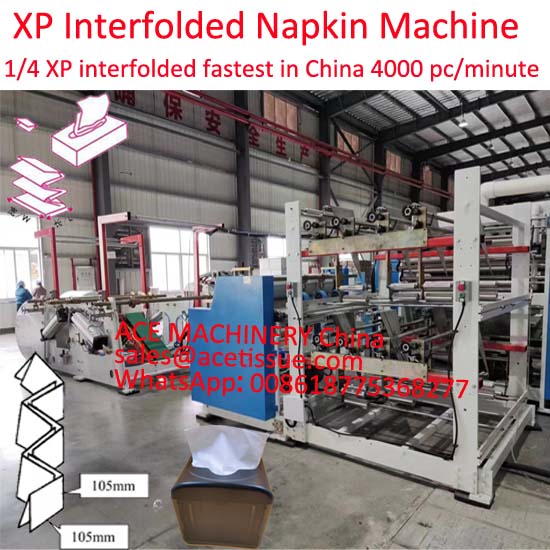

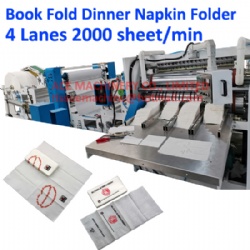

high speed 4 Lanes interfolded 1/4 fold xp napkin machine in China

Short introduction of high speed 4 Lanes interfolded 1/4 fold xp napkin machine in China:

1 High speed 4000 napkin per minute.2 4lanes output

3 fastest and best XP napkin machine made in China.

4 Can be with embossing and color printing.

5 Made in China.

Detailed technical specifications of this high speed 4 Lanes interfolded 1/4 fold XP napkin machine in China.

| XP napkin machine model | ACE-INM-4L high speed 1/4 XP napkin machine. |

| jumbo roll specifications |

a. Raw Material Jumbo roll specification:12-20 g/m² 2-ply tissue paper. Please confirm specific details. b. Jumbo roll size: ≤Φ1500mm x width 1320mm (330mm * 4lanes = 1320mm);(Other size available.) c. Jumbo roll core diameter:Φ76mm; d. Suitable for various napkin materials, including paper, tissue, and non-woven fabrics. |

| Finished 1/4 XP napkin sizes |

a. Finished XP napkin product: 1/4 XP napkin / interfolded napkin / pop up napkin / interleaved napkin/ table top napkin. 1/4 XP Napkin open size: (210x330mm) ± 2mm. 1/4 XP Napkin folded size: (105x165mm) ± 2mm. Fixed size(cylinder cutoff size) is 210mm ± 2mm. b. Folding type: 1/4 XP interfolded and Vacuum fold. |

| Output number of lanes | 4lanes output. Available 2 lanes, 6 lanes or 8 lanes. |

| XP napkin machine speed |

About 1000 napkin/minute/lane * 4 lanes = 4000 napkin/minute total, depends on tissue gsm, quality, operator etc. The fastest XP interfolded napkin machine in China mainland for now. |

| Jumbo roll unwinders |

a. With 2 jumbo roll unwinders back stands. b. Jumbo roll web tension is adjustable. c. Synchronism paper feeding unit. d. Pneumatic loading Jumbo roll automatically; |

| Folding Head |

a. Automatic counting unit. Counting quantity adjustable. b. With stepless-adjustment hand wheels to control web tension.

c. Folding type: 1/4 XP folded, interfolded & vacuum folding.

|

| Full embossing unit |

a. With 2 pairs of steel-to-rubber full embossing unit (one type of embossing pattern). (can be optional steel to steel to steel embossing to wool emnossing.) b. Embossing tension is adjustable to adapt the machine for different quality and gsm papers. c. Heavy duty desigh / Strong structure. to ensure high speed operation. |

| Control system |

a. Design speed: 120meters/min b. Operation speed: about 1000 piece/min/lane * 4 lanes = 4000 piece/min total, depends on tissue gsm, quality, operator etc. c. Speed of production is controllable. d. Main motor control by inverter e. Controlled by inverter, famous brand. f. Automatic counting system, each count of 100 pieces, 150pieces, 200 etc. adjustable. g. With JOG function for folding unit, embossing unit etc. easier for maintenance. h. With emergency stop function for folding unit, embossing unit etc. you can stop the machine in any cases of emergency. Good for safety protection. i. With paper break auto stop function. Machine will automatically stop if paper break or used up. j. Power: total power about 45 KW, (final Power is subject to actual power KW without further notice.) 3-phase AC380V 50HZ or customized. k. With vacuum pump. Less noisy, more energy-saving. l. Vacuum pump for adsorption (included in quotation.) m. Air pressure: 0.5Mpa(buyer supplied) n. Machine weight: about 4500kg. o. Machine size: 6000x2000x2100mm. |

| Certification: | Complies with relevant industry standards and regulations like CE. |

| XP napkin machine videos / photos |

For more details, please contact us: WhatsApp: 008618775368277 Skype: tissuemachine Email: tissuemachine@hotmail. [email protected] [email protected] Website: https://www.acetissue.com/ |

Application of 4-Lane XP Interfolded Napkin Machine in China:

The 4-Lane XP Interfolded Napkin Machine in China is widely used in various industries for efficient napkin production. It finds its application in:

1. Restaurants and Cafes: This machine is ideal for restaurants and cafes that require a steady supply of napkins for their patrons. It can produce a large volume of interfolded napkins, ensuring a constant and readily available supply.

2. Hotels and Resorts: Hotels and resorts use napkins extensively in their dining areas, banquet halls, and room service. The 4-Lane XP Interfolded Napkin Machine enables them to produce high-quality napkins in bulk, meeting the demands of their guests.

3. Catering Services: Catering companies often handle large-scale events where napkins are an essential part of the table setup. This machine allows them to efficiently produce interfolded napkins in different sizes and designs, ensuring a professional presentation.

4. Food Service Industry: Fast-food chains, food courts, and other food service establishments require napkins for their customers. The 4-Lane XP Interfolded Napkin Machine aids in the production of napkins that are convenient, hygienic, and easy to dispense.

5. Retail and Wholesale: Napkins are also sold in retail and wholesale markets. This machine can be utilized by napkin manufacturers or distributors to meet the market demand and supply napkins to various retailers.

6. Event Management: Event organizers often require napkins for conferences, seminars, weddings, and other gatherings. The 4-Lane XP Interfolded Napkin Machine enables efficient production to cater to the specific needs of event management companies.

7. Hospitality Industry: The hospitality industry, including hospitals, nursing homes, and assisted living facilities, utilizes napkins for patient care and dining services. This machine ensures a steady supply of hygienic and well-folded napkins to meet their requirements.

The 4-Lane XP Interfolded Napkin Machine in China offers versatility and efficiency, making it a valuable asset in various industries where napkins are essential.

Product Description of this high speed 4 Lanes interfolded 1/4 fold xp napkin machine:

Introducing the 4-Lane XP Interfolded Napkin Machine in China, a high-performance solution for efficient napkin production. This advanced machine boasts four lanes, allowing for increased productivity and seamless interlocking and folding of napkins with exceptional precision.

Designed with cutting-edge technology, the 4-Lane XP Interfolded Napkin Machine offers unparalleled efficiency and versatility. Its user-friendly interface and automated controls ensure smooth operation, while the robust construction guarantees reliability and minimal downtime.

With the capability to interfold napkins in multiple sizes and designs, this machine caters to the diverse needs of various industries, including restaurants, hotels, and cafes. Whether you require elegant napkins for fine dining or practical options for casual settings, the 4-Lane XP Interfolded Napkin Machine delivers outstanding results.

Experience enhanced productivity and superior quality with the 4-Lane XP Interfolded Napkin Machine in China. Elevate your napkin production capabilities and meet the demands of your customers with ease and efficiency.

Product Advantages of this high speed 4 Lanes interfolded 1/4 fold xp napkin machine:

High-Speed Production: The high-speed 4-Lane Interfolded 1/4 Fold XP Napkin Machine in China offers exceptional productivity with its advanced design. It can rapidly produce a large volume of interfolded napkins, maximizing efficiency and meeting high-demand requirements.Precise Folding and Interfolding: The machine ensures precise folding and interfolding of napkins, resulting in uniform and neatly stacked napkins every time. This consistency enhances the overall appearance and quality of the napkins, leaving a positive impression on customers.

Versatile Folding Options: With the capability to perform a 1/4 fold, the machine provides versatility in napkin styles and sizes. It can be adjusted to meet various customer preferences and requirements, allowing for customization and flexibility in production.

User-Friendly Operation: Equipped with intuitive controls and an easy-to-use interface, the machine enables operators to efficiently manage the production process. The user-friendly design reduces training time and promotes seamless operation.

High-Quality Construction: The high-speed 4-Lane Interfolded 1/4 Fold XP Napkin Machine is built with durable and robust materials, ensuring long-lasting performance and reliability. Its sturdy construction can withstand continuous operation and withstands the demands of high-speed production.